The right drill in the angle piece - easily selected

You want grinders? You get grinders. In the first part of our series on rotating dental instruments, we take a look at the different systems that we have to choose from in treatment. The almost infinite number of options actually presents all (future) dentists with challenges at some point: Which instrument can I use in which device? How can I keep track of my instruments - and what does the ISO number tell me again? Don't worry - we'll prevent panic attacks, sweating and confusion and answer the most important questions.

For now, an overview of the basics of rotary instruments is enough to choose from the huge range of products offered by manufacturers. There are a few things you should bear in mind: If you use a drill whose dimensions do not match the clamping system of your own contra-angle handpiece/handpiece, this can have serious consequences. Firstly, there is a risk that the shaft of the rotary instrument will spin in the collet and thus destroy the collet - or possibly come loose and fly out during treatment. This can end badly and cause trouble - so it is worth going over the basics again.

Which milling cutters and grinders fit into which clamping systems?

In everyday practice, practitioners can use a selection of different systems to work with rotating instruments.

The classic is of course the electrically driven contra-angle handpiece, where the rotational force is transmitted to the working head via a shaft. A distinction is made here based on the type of locking mechanism:

- RA shaft with manual locking

- FG shaft with smooth static friction

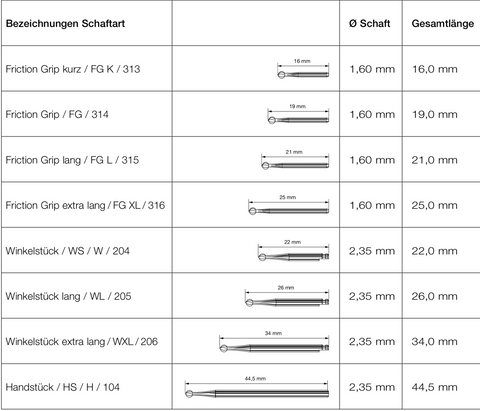

The RA shaft is 2.35 mm wide and slightly thicker than its smooth counterpart at 1.6 mm. The RA instruments can be recognized immediately by the locking notch at the end. The contra-angles that are attached to the micromotor also differ in terms of the speed ratio. Starting from a power of up to 40,000 rpm, for example, the red-ringed contra-angle (high-speed) can achieve a speed of the workpiece of up to 200,000 rpm with a 5:1 transmission. The slower blue and green contra-angles, with a transmission of 1:1 and 5.4:1 respectively, normally have an RA shaft. They are therefore designed for drills with a lock. This type of shaft is often found in polishers, rose burs for excavation and cutting discs.

The dental turbine can also be used. This is operated with compressed air and reaches speeds of up to 450,000 rpm. The speed cannot be regulated and the torque is also significantly lower than that of its electric counterpart, the red high-speed model. The clamping system also accommodates FG shafts.

Away from the mouth, especially for processing dental workpieces, the handpiece is a great way to achieve good results. This non-angled transmission instrument usually has no gear ratio and thus normally reaches speeds of up to 40,000 rpm. Instruments with a maximum shaft length of 44.5 mm can be clamped into the handpiece shaft - some manufacturers offer models that can hold both long dental milling cutters and angle drills.

The ISO number: easier than you think!

The shaft length and width is just one feature that you should keep an eye on when choosing the right instruments. To keep an overview of the other factors, it is worth looking at the ISO number as a clear aid: As an international standard, it provides information about the material of the working part, shaft type and total length, as well as the shape, design and size of the working part. ISO 6360 is structured in such a way that the respective feature can be immediately recognized from the number in the hundreds:

Although the ISO coding allows an instrument to be clearly identified, in everyday life its many digits lead to a complicated jumble of numbers. The ISO number is often also the order number. However, this means that when purchasing, you have to pay close attention to entering the correct numbers - quite cumbersome when there is a long list of numbers that need to be ordered. Experience also shows that, especially in larger practices, the overview of the various drills and grinders is lost. Dental assistants often complain that they have difficulty ensuring that there is a constant supply of the right drills in all treatment rooms. The consequence? The purchase of new rotating instruments is neglected.

What was that again about the color markings…?

One of the most important features of dental grinders? Grit! Unfortunately, manufacturers sometimes use different color markings for the different levels. In Germany, however, a system has been established that applies to most manufacturers:

- super coarse: black ring

- coarse: green ring

- medium: colorless or blue ring

- fine: red ring

- extra fine: yellow ring

- ultrafine: white ring

With these simple basics, you will have a clear overview of the grinder jungle the next time you go shopping - we wish you lots of success and fun!

Sources

W&H. Dental transfer instruments - what to look for when buying? Retrieved on June 19, 2021 from https://www.wh.com/de_global/dental-newsroom/berichte-studien/artikel/04451

Weber, T. (2016). Memorix Dental Medicine. Thieme

KAVO. Dental handpieces and contra-angles. Retrieved on June 19, 2021 from https://www.kavo.com/de-de/dental-instrumente/dentale-handstuecke-und-winkelstuecke

Hellwig, E., Klimek, J., Attin, T. (2010). Introduction to dental conservation. German Dentists Publishing House

Image: www.oridima.de